شمعات الإشعال ذات التوليد المشترك

تُعد DENSO واحدة من الشركات الرائدة في العالم في مجال ابتكار وتصنيع تكنولوجيا الإشعال، بما في ذلك شمعات الإشعال. لقد كنا أول شركة تنتج شمعات إشعال إيريديوم طويلة العمر للسيارات، واخترعنا أصغر طرف إيريديوم وأكثره كفاءة في العالم بقطر 0.4 مم.

قامت شركة DENSO أيضاً بتطوير شمعات الإشعال من الإيريديوم CoGeneration - وهي مجموعة فريدة من شمعات الإشعال من الإيريديوم القوية وعالية الأداء خصيصاً لصناعة محركات الغاز.

تجمع شمعات الإشعال Iridium CoGeneration بين جميع مزايا الأداء لتقنية Iridium Spark Plug من DENSO مع عدد من مزايا الكفاءة الإضافية. اختر من بين Iridium Saver وأحدث Iridium Saver DDI.

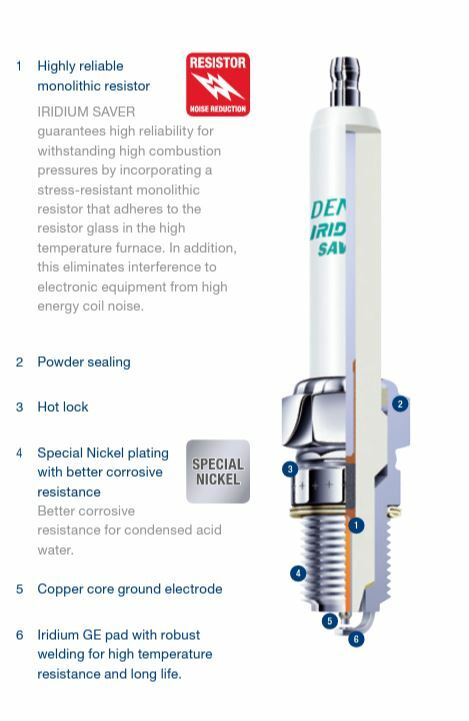

Iridium Saver

Features

- Highly reliable monolithic resistor. Iridium Saver guarantees high reliability for withstanding high combustion pressures by incorporating a stress-resistant monolithic resistor that adheres to the resistor glass in the high temperature furnace. In addition, this eliminates interference to electronic equipment from high energy coil noise.

- Powder sealing

- Hot lock

- Special Nickel plating with better corrosive resistance; with better corrosive resistance for condensed acid water.

Advantages

- Reduced maintenance costs

- Extended plug life

Specifications

- Iridium alloy pad + platinum alloy pad; The Iridium alloy pad (developed and patented by DENSO) is located on the centre electrode. A platinum pad is located on the ground electrode. The two pads help to provide excellent wear resistance compared to conventional spark plugs.

- Dielectrical resistance welding (ground electrode); DENSO achieves superior performance by accurately controlling the welding conditions.

Iridium Saver DDI

Features

- Highly reliable monolithic resistor: Iridium Saver guarantees high reliability for withstanding high combustion pressures by incorporating a stress-resistant monolithic resistor that adheres to the resistor glass in the high temperature furnace. In addition, this eliminates interference to electronic equipment from high energy coil noise.

- Powder sealing

- Hot lock

- Special Nickel plating with better corrosive resistance: Better corrosive resistance for condensed acid water.

- Iridium GE pad with robust welding for high temperature resistance and long life.

Advantages

- Proven longer plug life: Iridium pads located on both the centre electrode and the ground electrode (hence DENSO Double Iridium - DDI) minimise spark gap expansion, ensuring a longer plug lifetime.

Specifications

- Double iridium alloy pads: the Iridium alloy pads (developed and patented by DENSO) are located on both the centre electrode and the ground electrode. The two pads dramatically improve wear resistance compared to other Iridium plugs by minimising spark gap expansion.

- Convergence laser welding: wedges created by laser welding fix Iridium alloy pad securely on the ground electrode. Delivers high reliability in high temperature combustion engines.

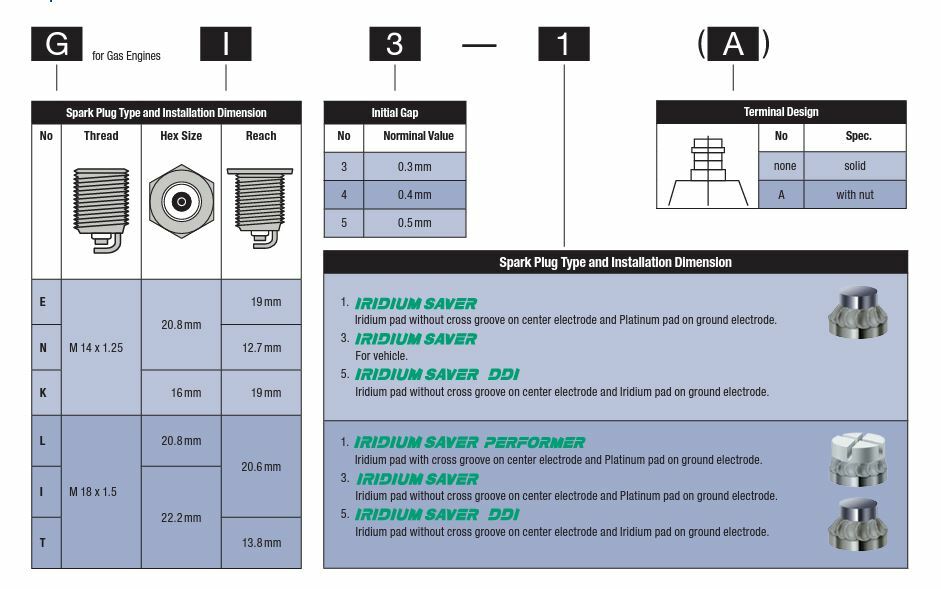

Identifying DENSO Co-Generation Spark Plug

Installation & Fault finding

Installation

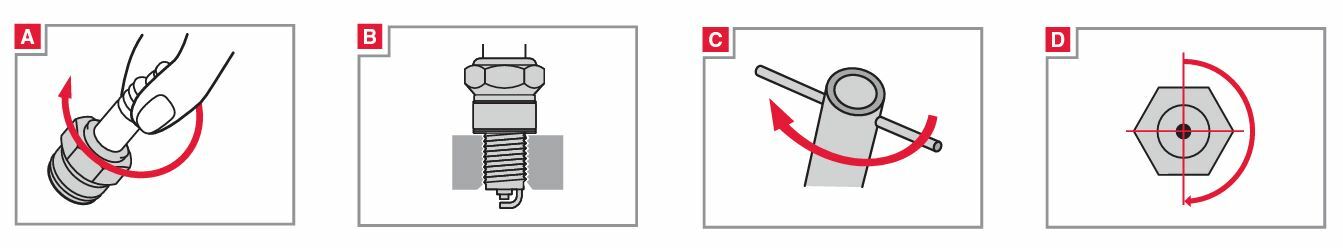

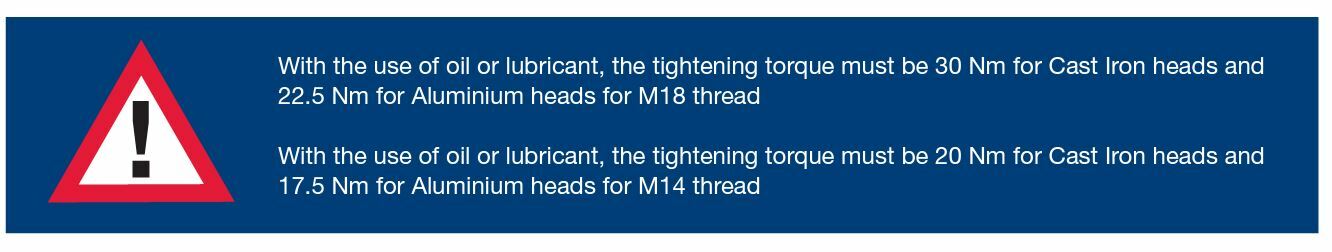

Recommended Torque and tightening angle

- Use the correct wrench for the hex on the plug, and be careful not to damage the insulator.

- When changing, make sure that no foreign substance falls into the combustion chamber.

- When putting the plugs in, make sure that all cylinders are clean.

- Make sure the plugs are vertical, then tighten them by hand until they cannot be tightened any further (A+B).

- Then, use a spark plug wrench to tighten them accurately according to the recommended torque specifi cation (C+D).

DENSO recommends using lubricant on the thread.

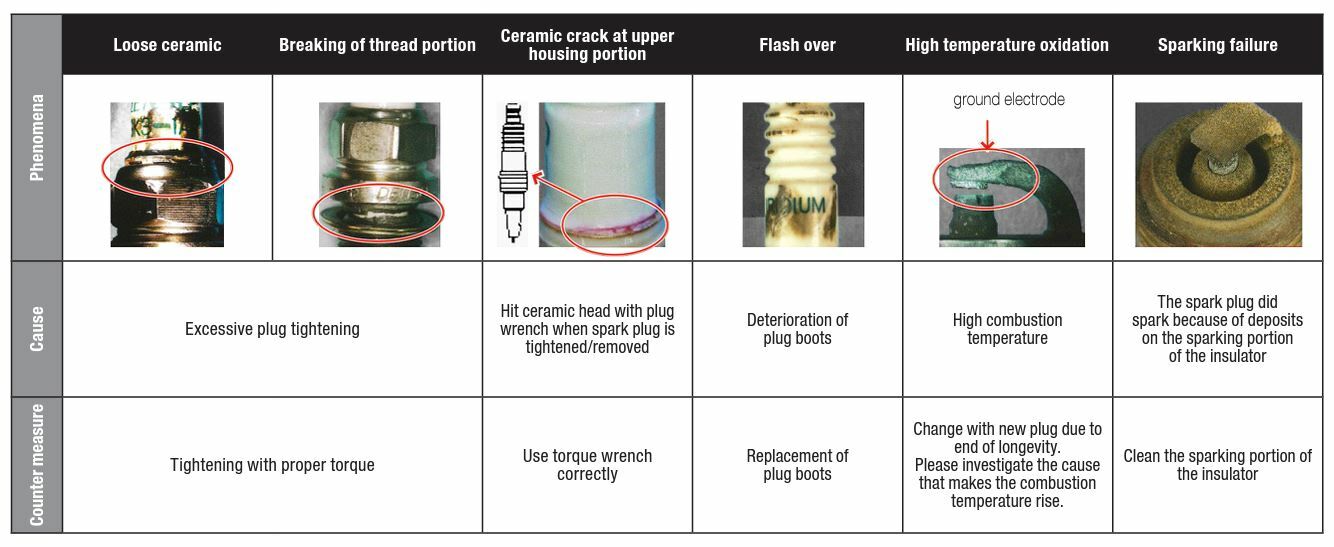

Fault Finding

An effective way of diagnosing the engine’s operating condition is to check if the spark plugs look

abnormal. If all cylinders are operating normally then the spark plug appearance is light grey, there are tanned deposits and there is a slight electrode erosion.