Rotary distributor-based diesel fuel injection pumps were an industry standard for years; however, as emissions standards for new vehicles became stricter, their mechanical control systems could no longer deliver the precision control over fuel injection that was required.

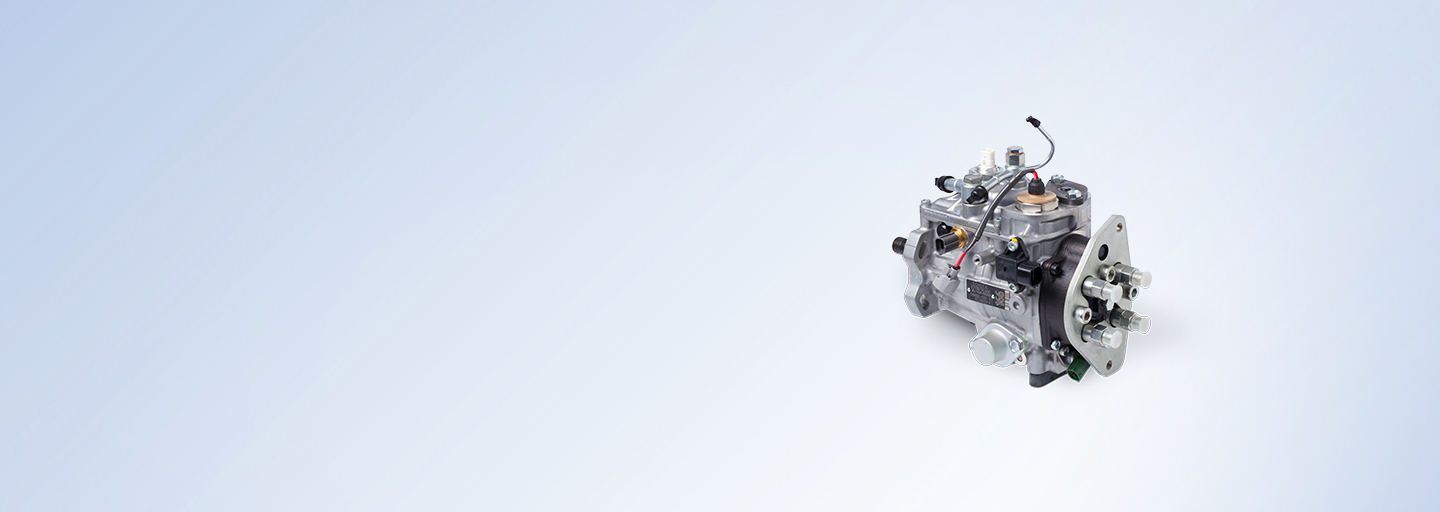

The electronically controlled diesel (ECD) pump was a result of these increased demands. It electrified the distributor pump system, introducing various sensors, an electronic control unit (ECU) and an actuator. Various sensors detect running conditions and send this information to the ECU, which controls the actuator to constantly adjust fuel injection quantity and timing, depending on the state of the engine. When a certain volume or injection timing would be optimal for combustion, an ECD pump can adjust the fuel supply and timing to match this demand.

Fuel is still being pumped, via mechanical injectors, directly into each cylinder – but electrifying the process through ECD pumps means a diesel engine can achieve higher levels of performance and efficiency, allowing it to meet stricter emissions regulations.