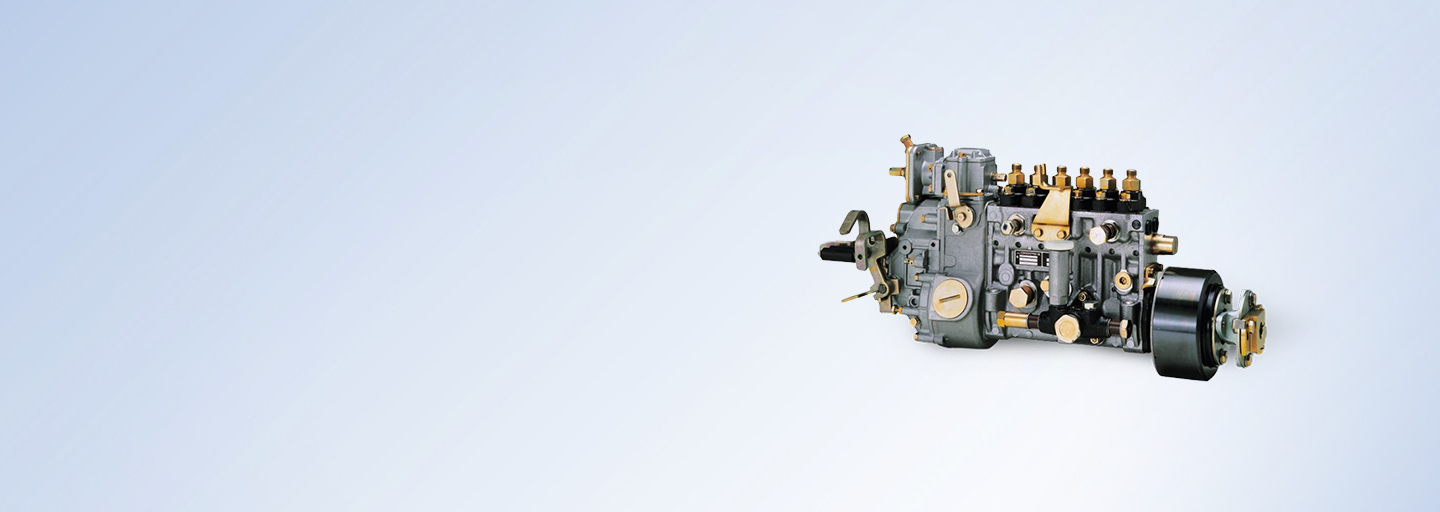

There are two main types of mechanical pump systems for diesel engines: in-line fuel injection pumps and distributor injection pumps. Often seen in older vehicles, medium to large trucks and construction machinery, they are key parts of more traditional diesel engines.

Mechanical pump systems

DENSO provides the original OE high-quality mechanical pump systems for all types of DENSO system-equipped diesel engines.

Mechanical pump systems

How DENSO mechanical pump systems work

Features and benefits

-

Wide range of engine and vehicle applications

-

Features a governor, timer, and feed pump

-

Original, reliable engine performance

Types and characteristics

Mechanical pump systems types

In-line fuel injection pumps work by feeding fuel from the pump body into each engine cylinder according to the injection order. There are the same number of fuel pressure mechanisms (elements) as engine cylinders. The fuel is injected from the pump body under pressure, via the injectors, into the engine cylinders via feed mechanisms and injection quantity control mechanisms. These are driven by the camshaft. These types of pump are mainly used in medium and large trucks and construction and agricultural applications.

The distributor injection pump has only one fuel pressure mechanism, irrespective of the number of engine cylinders. The pump has a distributor to supply cylinders with fuel according to the injection order. All the components, including the governor, timer, and feed pump, are built into the pump housing. This small, light pump can operate at high speeds, and is often seen in smaller engines.

Characteristics

Many years of research and development have enabled us to produce reliable and high quality in-line and distributor fuel injection pumps.